FITS AIR product information

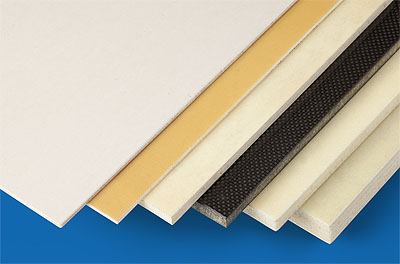

FITS AIR panels consists of a PEI in-situ foamed foam and a fiber reinforced PEI(PPSU,PES) consolidated facing.

Due to its totally thermoplastic nature FITS AIR panels can be shaped and formed in seconds, with very low added weight

(< 5%). Therefore the products manufactured from FITS AIR panels generally have a 10-40% lower weight then the parts from the nowadays applied materials like: Nomex Honeycomb, Foam or Alluminium. The automated high speed application technology gives significant cost savings especially at higher production rates. Other advantages of the FITS AIR panels are:

- Very good insulation

- Very low flammability and smoke density

- Very high peel strength

- No fungus

- We do expect a longer lifetime of the FITS products

- FITS parts are recyclable

Product applications are:

- ceiling and sidewall panels.

- trolleys, dado panels

- luggage bins

- galley

- toilets

- sidewalls

- PSU panels

- and so on

FITS AIR panels can be manufactured with a thickness of 3.2 upto 25 mm ,

with a in-situ foam density of min. 80 – max 250 kg/m³.

Facing thickness t = 0.1 mm - 0.6 mm.

The facings can be colored to customer request.

Printing decoration by transfer printing is also possible.