FITS BASE Thermoformable Panels

Currently, the available sandwich panels for high speed, low cost large series part-production for automotive and other large markets do not fulfill the requirements for the industry. These panels either lack: high speed processing; thermoformability (honeycomb); low weight (injection molding); recyclability (combining multiple plastics), or low cost.

FITS developed a revolutionary process to manufacture low cost strong FITS BASE sandwich panels. These FITS BASE panels can be manufactured of Polypropylene or similar low-cost plastics. For the sake of convenience, however, we use PP in this text for all low-cost polymer options.

Our FITS BASE panels bring all what is required:

- Low cost panel manufacturing technology

- High mechanical properties combined with low weight

- Automated thermoformable application technology

- Large market potential

Low cost panel manufacturing technology

Thanks to the highly automated processes, FITS BASE panel cost is based on the material cost of PP(PolyPropylene) and fibers plus a modest manufacturing cost. Total manufacturing cost of FITS BASE panels is significantly below the current PP honeycomb panels.

The technology and manufacturing process FITS BASE panels can be manufactured in a batch (press) or in continuous process (with a belt press) in minutes at high volumes.

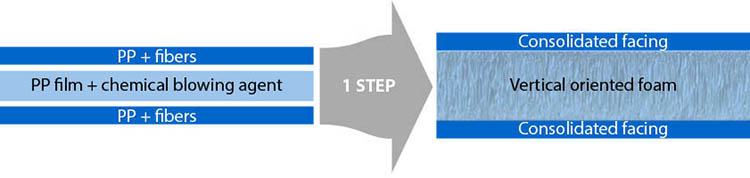

If we already have consolidated fiber reinforced thermoplastic PP-facings available, thermoplastic PP-films with a chemical blowing agent are placed between those facings(pack) before the in-situ foaming is created.

To make the manufacturing process for FITS BASE panels even cheaper, the facings can be manufactured in the sandwich manufacturing step. This is revolutionary and unprecedented in the industry.

PP materials and fibers are placed at both sides of the PP-film impregnated with chemical blowing agent and the following process steps are executed:

- These packs are heated under high pressure creating the facings

- The total pack is cooled down to just above melting temperature

- The pressure is released, and the press is opened allowing the blowing agent to create foam

- The specific opening curvature ensures the creation of vertical cells for high compression strength panels

- At the end of the foaming curve the FITS BASE panel is cooled down to the required temperature

In this globally patented process, the consolidation of fiber reinforced PP facings plus in-situ foaming of the PP foam core has created a thermoformable FITS BASE panel in just one step. In minutes, a strong, low-cost sandwich panel is created by just using low cost automated processes from low cost materials.

Notes:

- These packs are heated under high pressure creating the facings

- The total pack is cooled down to just above melting temperature

- The pressure is released, and the press is opened allowing the blowing agent to create foam

- The specific opening curvature ensures the creation of vertical cells for high compression strength panels

- At the end of the foaming curve the FITS BASE panel is cooled down to the required temperature

- In an alternative embodiment of manufacturing a sandwich panel using a chemical blowing agent, cooling is started just prior to increasing the distance between the press plates in order to solidify (fibre-reinforced) thermoplastic skins, while the thermoplastic core layer containing the decomposition products of the chemical blowing agent is still at the homogenous foaming temperature. A sandwich panel thus obtained shows an excellent appearance and possesses favourable mechanical properties.

Low weight paired with high mechanical properties

FITS BASE panels are low weight. The total weight of e.g. a standard 10mm panel is approximately 2.5 kg/m². The low weight is the result of:

- The strong light weight high compression strength foam

- Very high peel strength

- Strong light weight fibers in the facings

- Absence of adhesive layers between facing and core

Therefore, FITS BASE panels have a lower weight than comparable panels with a similar strength. Compared to Honeycomb panels, FITS BASE panels do have comparable mechanical properties in the area of high stiffness/strength and low weight. FITS BASE panels however, besides having the benefit of thermoformable processing, have a series of other benefits over honeycomb panels:

- FITS BASE panels are homogeneous, with no length/width direction. FITS BASE panels with similar in length strength are stronger in width

- FITS BASE panels have no weak edge effect

- FITS BASE panels have a higher peel strength

- FITS BASE panels have higher structural integrity

- FITS BASE panels have smooth surfaces and no telegraphing effect

- FITS BASE panels have a better insulation for heat and noise

- FITS BASE panels are waterproof

- FITS BASE panels are fully recyclable

Automated thermoformable application technology

FITS BASE panels not only have superior properties, they also have excellent thermoformable capabilities. These capabilities stem from the fact that FITS BASE panels are made of a homogeneous distributed, high compression strength PP thermoplastic core combined with fiber reinforced PP thermoplastic facings. Dedicated automated thermoforming machines can shape and form FITS BASE panels into consistently high-quality parts in matter of seconds.

Some examples of these thermoforming possibilities are: Edge finishing, folding panels or edges, 3D forming, reinforced edges, welding inserts and 3D printing.

The automated thermoforming processes of already low-cost panels, makes FITS BASE the solution for lowest part cost paired with very low part weight and recyclable.

The FITS System with FITS BASE panels meets all requirements for low cost, large series, low weight production of strong and stiff parts; for now, and in the future.

Large market potential

Thanks to the thermoformability and related high-speed part manufacturing, the low cost and very good mechanical properties, we envision a large potential for FITS BASE panels and parts applied in all kinds of markets.

Applications:

- Cars (e.g. Floors, door, seats, battery housing, bonnets)

- Solar Panels

- Buildings, furniture and construction

- Caravans and campers

- Shelters, low cost housing for low wage countries

- Cheap replacement for honeycomb panels (lift & drop)